Portable Saw Mill Success Story

Posted by Stephen Cook on Jan 9th 2019

An AC-36 Portable Sawmill Success Story.

t is really good to know Harry Page and have him for a

friend. He is certainly enjoyable to talk with and is fun to

be around.

He is also smart and knows how to work as you will see in

his story. You can see that the Accu-trac 36 portable sawmill

can produce a massive amount of lumber in one day. Harry has

sawn up to 5,500 board feet in a day when the conditions are right.

How Much Lumber Can You Saw Using a Accu-Trac 36 Portable Sawmill?

We, want to be very honest and reasonable, so we are careful not to over promote the board footage that we say can be sawn in a day. Numerous customers tell us they can saw more than 5,000 board feet a day. But in all fairness you will probably average 3,000 to 3,500 board feet a day. If you go the extra mile and plan your day you will often do better... much better. This will be worth your time spent because it will make you thousands of extra dollars.

Again Harry, thanks for your story. You are our inspiration. ~ SC

“Have sawmill, will travel” could easily be Harry Pages’ blueprint for success.

Following story written by Harry Page.

I started out in Jan. 1996 with another well know hydraulic saw mill. It was much smaller than the Cooks Accu-trac I now own. I have traveled across Alabama, Louisiana, Florida and East Texas.

The first saw mill I bought came with no instructions so I taught myself through trial and error. I learned real soon to sacrifice speed for quality. I wanted to burn the first lumber I cut.

It wasn't that great but after about 3 months I got the hang of it and it became natural to me. I do things a little different from the way others do. I guess I could say I have bought my lessons.

In the beginning there was an obstacle I had to overcome. The lack of customers. Nothing was going to get me down because I love people and I love to talk and make friends.

I started talking to everyone I came in contact with, handing out business cards and telling them about my saw mill business and no paid advertising was done.

"I was able to build my business because I take my saw mill to the logs. It's a lot easier for the customer than having to load and haul their logs to and from the saw mill. There are several other saw mill operators within a few miles of me but a lot of people don't want to travel over 15 or 20 miles. Me... I go where the business is."

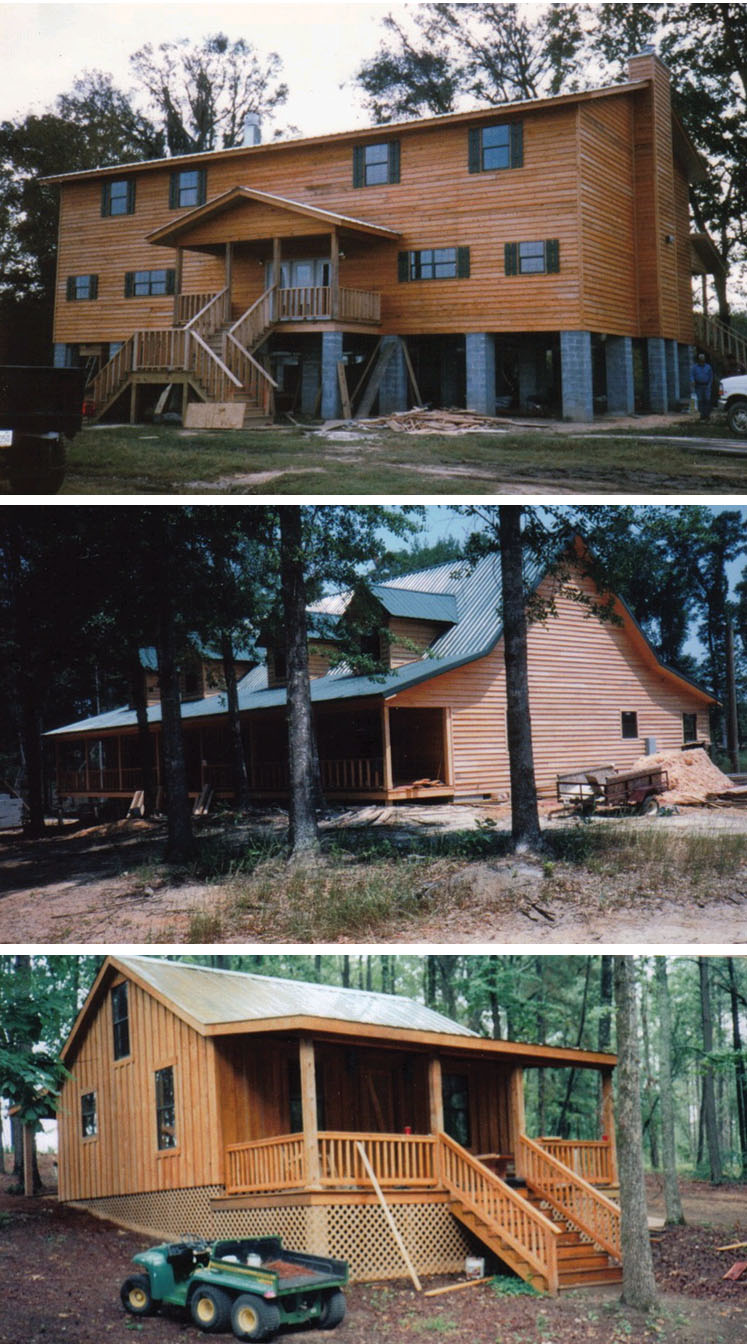

My sawing jobs have ranged from short 1 day jobs to 6 weeks. I have a minimum of 1,000 board foot per job. I've had a 6 week job cutting lumber for a 2 story hunting lodge in Statesville, Alabama in 1997 (where I stayed at a hunting camp until I finished the job). I cut all cypress for the 5,800 square foot buildings exterior and the interior paneling.

My only marketing tools are business cards and word of mouth, because I have built a very good reputation of treating my customers the way I want to be treated, so word of mouth is my best advertising."

I also cut 1x1 stacking sticks free of charge for my customers. I believe because of these things I have many repeat customers. My customers advertise for me. They say, “Don't let anyone saw your lumber but Harry Page.” I don't mean to sound conceited, but that’s what I have been told over and over. My customers aren't just customers, they are my friends!

On another job I stayed 6 weeks in Baker Hill, Alabama cutting lumber for a company whose saw mill had burnt. I kept enough lumber sawed to keep his pallet mill going.

I bought my Cooks Accu-trac 36 portable saw mill in 2000 because the other brand was too small. WHAT A DIFFERENCE THE LARGER ACCUTRAC PORTABLE SAWMILL MAKES!

If the conditions are right and there are enough helpers, I have sawed over 5,500 B.F,T, in one day. My other mill could only saw up to 1,500 B.F.T. a day. I started buying band saw blades from Cooks Saw Manufacturing in 1997.

I also bought a Cat Claw band saw blade sharpener in 1997, which was the best $1,500.00 I have ever spent. Its a wonderful sharpener. When I bought my Cooks Accu-trac portable saw mill with a 58 horsepower Volkswagen engine, I bought the best I could buy including a lap side resaw.

My production jumped 60 or 70% with my Accu-trac portable saw mill. I have cut 200,000 board foot for one customer north of Prattville, Alabama, and also 10,000 board foot of lapsiding that he has used to build 3 Chalets in Gatlinburg, Tennessee. I have also sold enough lumber for 2 friends to build their houses and they still have enough to build 2 more Chalets.

Last year 2002, Columbia Pictures was making a movie called Big Fish in Montgomery and Wetumpka, Alabama and one of my customers recommended me to them. They ended up buying over 15,000 board foot of cypress lumber from me.

I have been on the front page of the Troy Messenger Newspaper in Troy, Al. and on WSFA channel 12 on a short news show called County Road 12 featuring me with my sawmill. I have also been featured in an article in the Timberline news magazine out of Richmond, Virginia.

To my recall, I have cut enough lumber to build approximately 20 houses, numerous barns and cabins, fence material, beams for million dollar homes, you name it, I've done it. I can truly say that my Cooks Accu-trac Saw Mill has really made my business a success and when you need band saw blades and parts, Cooks Saw Manufacturing Co. is the best for customer service and THEY TREAT YOU RIGHT.

Sincerely Yours,

Harry Page

Very Happy Saw Mill Owner!