Find Your Niche in Lumber Sales and Custom Wood Work - Customer Spotlight

Posted by Admin on Jan 8th 2019

Weekend Sawyer Paul Leverenz Finds Niche In Lumber Sales and Custom Wood Work.

rticle Courtesy of "Today Publication"

NEW HOLSTEIN – Learning to cut down trees and turn them into quality lumber is not an education that can be rushed, said Paul Leverenz.

But the payoff for his carefully developed part-time business has been not only modest profits, but the satisfaction of working with friends and family to turn out quality, specialized wood products.

"Part of it is my nature: I like to work," Mr. Leverenz said.

"It’s a great way on the weekend for me to unwind, do some physical labor, carry some logs around, smell the stuff." During the week Mr. Leverenz directs the Easter Seal’s Agribility Program for Wisconsin, which is dedicated to helping farmers handicapped by accidents or health problems keep farming.

On the weekends, he manages two 20-acre parcels of woods, one of them part of the family farm. He harvests and saws trees and sells the air-dried lumber, as well as providing custom sawing services for others. The work has allowed Mr. Leverenz to keep working on the family farm, though the cows were sold in 1987, ending his hopes of becoming a dairy producer. Mr. Leverenz said he spent $7,200 to have a Cook's Saw 20-horsepower manual bandsaw sawmill delivered to his door in 2000, and paid extra for the bigger motor while skipping the hydraulics. He’s never regretted that decision, he said.

The set-up allows him to saw about 1,500 board feet in an 8 or 9 hour day, with one person helping, he said. "I’ve come to the point where if I saw for somebody, they’ve got to provide somebody to saw with me. "Instead of hydraulics, he uses a tractor with a two-tined fork in place of a bucket on the front end to load the logs onto the mill. "There’s a lot of things I like about the manual sawmill," he said. "You’re right next to it. You can hear the motor, see the sawing."

In the last two years, Mr. Leverenz said, he has sawn on average between 25,000 and 30,000 board feet per year. About 40 percent of that came from his family’s woods, and 60 percent was custom work, he estimated. He averages a total of 18 days a year sawing, and nets $2,000 to $3,000 per year after expenses, he said. But there is also plenty of time spent in the woods, he added, working on harvesting, thinning, clean-up, and other management tasks. For these jobs he recruits friends, family, and deer hunters, he said.

Although he doesn’t hunt deer himself, he allows hunters on the land. "People don’t understand the real impact that deer are having on woodlots," Mr. Leverenz said. He didn’t either, until a forester demonstrated that foraging deer were the reason that no oak or cedar were regenerating in his woods. Deer hunters not only help control the deer, Mr. Leverenz said, they are friends who are happy to help out for a couple days a year in exchange for hunting privileges. "If I had to pay people for all the time that I put into the woods, I would not be profitable," he said. "People who are willing to trade off some labor are what make it profitable."

Niche marketing is another key to staying in the black, Mr. Leverenz said, and fits with his sustainable forestry practices. "It’s finding opportunities to use those things that normally would go in the firewood pile," he said. Sustainable forestry means, in part, managing a woodland so that the best trees are left until last, in order to reach their maximum value. Trees that are less desirable, either because of their species or their shape, are harvested first, and harvests are done bit by bit, rather than all at once.

This results in smaller, more frequent timber harvests, with less disturbance to the woods, and standing timber that increases in value each year. The trick is to find a market for the less commercially desirable timber harvested in sustainable forestry. "So much of it is just being able to help people understand what the options and opportunities are," Mr. Leverenz said.

And in turn, he said he spends a lot of time talking to others in the wood business, such as a friend and neighbor that does cabinetry work and helps Mr. Leverenz "understand what woodshops want." For example, poppler makes a lumber that can be used instead of pine, and hickory, though it doesn’t grow big enough to interest commercial loggers, is used by custom cabinet makers.

Mr. Leverenz was able to sell a too-short cedar log for a fireplace mantel, and on one happy occasion he cut a slab for a bar top from a tree that a customer had grown up with. "I got a lot of joy" from that commission, Mr. Leverenz said. "I respect that people work really hard to bring you a piece of material that may not look good but may be their favorite tree."

He sells air-dried lumber from home, and he also will sell green lumber to a friend who operates a kiln, or to others who use it for milling. Another acquaintance has a laser engraving business, and "he will take really ugly logs" for use as plaques, Mr. Leverenz said. "Part of it isn’t being jealous about somebody else making money off of what you’re doing," he said. That way, "there isn’t a whole lot that goes to waste."

Mr. Leverenz said he has never advertised, but once he established himself as turning out good quality lumber, he has never lacked for custom work, though he won’t take on big jobs. "I’ve had people who call and say I’ve got 8,000 (board) feet, and I say call somebody who has a big hydraulic sawmill," Mr. Leverenz said.

But with the growth of his business, he is trying to decide if he should buy a bigger, hydraulic sawmill. On the other hand, Mr. Leverenz said, "It’s not about what you get done in a day, it’s about having more money at the end of a day." But money may not be the biggest motivator for Mr. Leverenz.

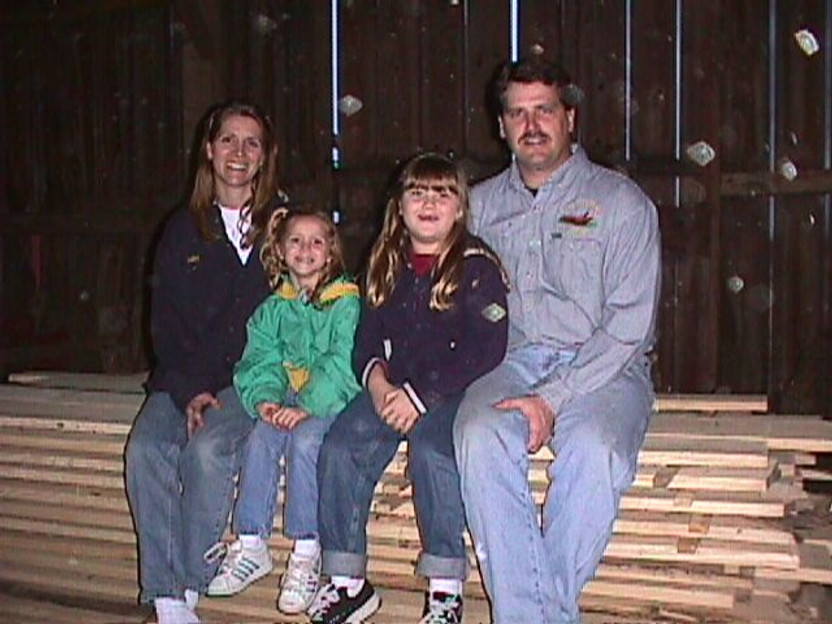

He and his brothers recently remodeled their parents’ home with tongue-and-groove white ash cut from their woods, and built an outdoor cedar ramp for their grandfather, "because he couldn’t do the steps anymore," Mr. Leverenz said. This summer, his mother agreed to watch Rachel, 7, and Erin, 5, so that Mr. Leverenz and his wife, Julie, would not have to worry about daycare. His mother wouldn’t accept any pay, but wanted a play set for the kids.

"So a couple of the brothers and dad got together one day, and in three or four hours sawed up what we needed," Mr. Leverenz said. "We took it up to the yard and built the playset." "How do you put a value on that? We’ll always be thinking about the day we built the playset." "I’m really pleased that the mill is paying its way," Mr. Leverenz said, "but it’s not all about money."