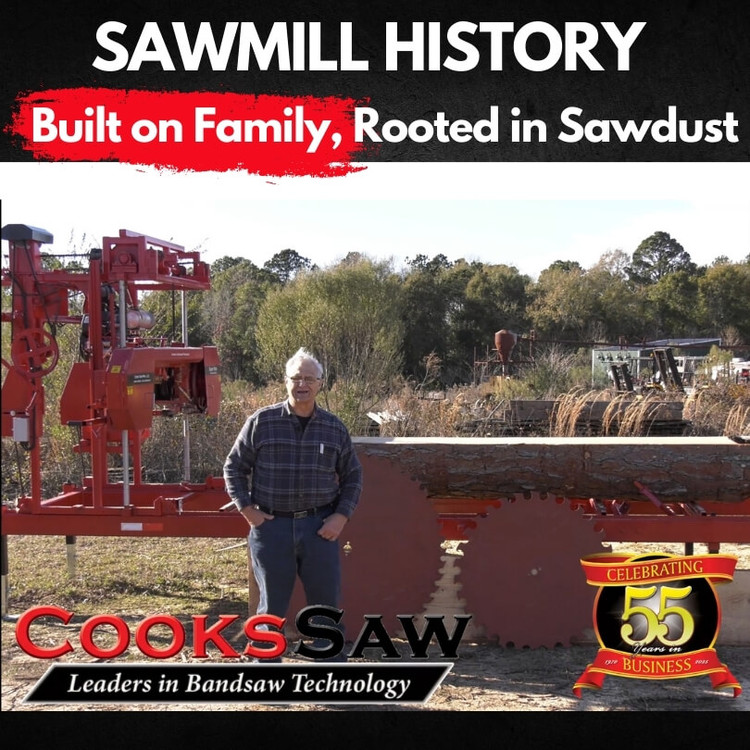

SAWMILL HISTORY | Family, Teamwork & Sawdust

Feb 10th 2025

Join Stephen as he takes you back to the Cooks family roots, where his father—a dedicated small-town preacher with a relentless work ethic—transformed a simple saw repair business into a powerhouse of American-made ingenuity with his family by his side.

The Humble Beginnings – Saw Repair & Blade Sharpening

In the late ‘60s and early ‘70s, Cooks Saw’s history with saw blades really began. Stephen, the youngest in the family, was only 7 or 8 years old at the time, while his brothers, Tim and Danny, were 10 and 12. Their father was a preacher in Wicksburg, Alabama, and with three growing boys, he wanted to provide more for his family. Instead of asking the church for a raise, he asked if he could start a saw repair business to supplement his income.

And just like that, the Cooks' legacy in sawmilling was born.

Using an old VW Bus (which would be worth a fortune today) and a grinding machine, their father started sharpening carbide saw blades. Before long, a local circle sawmill owner asked if he could repair his Frick mill blades. This was no small task—sawmill blades were 42 to 60 inches in diameter and needed hammering and rolling to maintain their rigidity under intense cutting pressure. With a blacksmith’s touch and an engineer’s mind, he mastered the skill.

Within a few years, he became known as the “Hammer Man” for sawmills all across the region. This wasn’t just about fixing blades; it was an art—an almost secret trade passed down among craftsmen who knew the power of a perfectly tuned saw.

Curious about our story? Read Legacy in Motion: A Personal Message from Stephen and learn more about the timeline behind Cooks Sawmills, and how a passion for serving others helped us create the sawmill equipment we have today.

Growing the Business – From Blade Repair to Manufacturing

As the business grew, Tim and Stephen jumped in, learning everything they could about saw maintenance. Tim became skilled at hammering saws, while Stephen spent years replacing thousands of carbide teeth in gang saws. In fact, Tim likes to joke with dentists that they’ve worked on more teeth than they have—just saw teeth, though.

The business expanded as their father started making weekly routes, picking up blades from sawmills hundreds of miles away, repairing them, and returning them the next week. This wasn’t just about sharpening anymore—it was about keeping sawmills running, saving sawyers money, and helping them maximize their production.

The Transition – From Repair to Building Sawmill Equipment

As Tim and Stephen graduated and began working full-time in the family business, they saw an opportunity. Why just repair saw blades when you could build the machines that keep them sharp?

With that vision, they began manufacturing bandsaw blade sharpeners in the early ‘90s. But that was just the beginning. Their father had also purchased an old machine shop, which housed tools that had been used on massive Navy ships—some of which were rumored to be from Noah’s Ark (or at least that’s what they joked about).

With these tools, the Cooks became machinists, learning the craft of metalworking and equipment building. The first major milestone? The AC36 Hydraulic Portable Sawmill—a sawmill that set the standard for performance and durability. Soon after came the MP32 Manual Mill, offering sawyers a more hands-on, budget-friendly option.

Where We Are Today – Innovation & Growth

Fast forward to today, and Cooks Saw is a leader in sawmill equipment, building some of the widest cutting portable sawmills in the industry—ranging from 44” to a massive 62” in diameter. The same work ethic, ingenuity, and hands-on experience that built the business decades ago still drive Cooks Saw today.

Their sawmills, blade sharpeners, and skid steer grapples are built with one thing in mind—helping sawyers cut more, cut better, and cut smarter.

The Legacy Continues

At Cooks Saw, we’re still those same boys at heart—driven by passion, curiosity, and a desire to build the best sawmilling equipment available. The business may have grown, but the core values remain the same:

✅ Work hard.

✅ Treat people with honesty and integrity.

✅ Never stop innovating.

This is where Cooks Saw began—and the best is yet to come.

Learn More of Sawmills & Bandsaw Blades

Explore our lineup of sawmills, blades, and sharpening equipment that keeps sawyers running strong.

Cooks Saw started with a VW Bus and a grinding machine, but it’s now helping sawyers across the country maximize their production. Whether you’re running a small mill operation or cutting on a super wide sawmill, we’re here to help you saw smarter and make every blade count.

Got questions? Reach out—we’d love to help.

Cooks Saw – Built by Sawyers, for Sawyers.