Straight to the point...Blades and Sharpeners

Posted by Tim Cook on Jan 10th 2019

So what’s the big deal about sharpening equipment?

Today’s market is full of products that claim to be the best. Here are some quick facts that you should know about when it comes to “proper sharpening equipment.”

If you’re like most new millers out there sawing for profit, you’ve probably thought of owning blade sharpening equipment. “Why should a sawmiller purchase a sharpener and take the time to master sharpening his own bands?”

My first answer is because a very keen blade cuts better than a new blade. Why is this? I’m glad you asked...

The answer begins with an understanding of tooth load. Tooth load is the amount of pressure and hp (horesepower) that it takes to pull one tooth through the wood with a specific tooth bite. The tooth bite is the depth of cut into the wood. Of course, softwood with a .010” bite is less of a load than hardwood at .010” bite per tooth.

If a band is keenly sharp the tooth load will be the lowest possible. Those of you who saw, know what I am referring to. When you put that new properly made bandsaw on your mill, you can tell the tooth load is low because of the sweet sound; the low hp pull while getting good feed rates. Those of you who use fuel motors have to go by sound and all who use electric motors can use ampere meters to know exactly what the load is by the amp pull. By the way, the amp meter is an excellent way to know how dull a band is and how much tooth load you have.

Here are three things to keep in mind that make the tooth load vary from high to low:

1. Sharpness

2. Feed Speed

3. Hardness of the Lumber

How do these three vary as a person saws?

#1. Sharpness - the band starts out whether it is new or freshly sharpened at what I consider the lowest possible tooth load for the moment but starts to progressively dull as the band makes each cutting pass. More precisely, each time the tooth comes around and strikes the wood it takes on some measure of dulling. Of course, the harder and more abrasive the wood, the faster it will dull. The band runs its best in the first hour and with each minute or hour it saws it takes on a greater load because of dulling.

#2. Feed Speed - it can vary according to the sharpness or width of cut or hardness of wood. Of course it is wise to slow down as the band dulls to keep the tooth load down but you will ultimately reach a point where it will not pay to saw so slow.

Special note to the reader: I mentioned lumber width and I want to give an understanding so as not to mislead any. The tooth load is considered as per tooth per square inch. We cannot consider a long strip of the band, instead we have to consider only the distance from one tooth to another tooth. Then we can say tooth load per square inch. This is because each tooth takes a bite that stretches the gullet immediately in front of the tooth. Tooth load equals body stretch and gullet stretch. We all know that a given band will saw a 6 inch wide board at a faster rate of feed speed than a 12 inch wide board. But which one is giving the greatest tooth load or band pressure per square inch?

Let’s use an example, if we cut a 12 inch wide cut at 30 ft. per min. then cut a 6 inch wide cut at double the feed speed of 60 ft. per min. Which has the greater tooth load and pressure per square inch? Let’s say just for example sake that the 12 inch cut has a tooth bite of .005” per tooth, then the 6 inch cut will have a bite of .010” per tooth. You can easily understand that we are putting twice the pressure against the bandsaw body especially in the gullet on the 6 inch cut than we are on the 12 inch cut.

One might say that the 12 inch cut pulled the motor harder or pulled more amps on electric. The fact is that’s true but you have twice as many teeth in the cut. That is why the motor load is greater but the band stress per square inch on the 12 inch cut is less than the 6 inch cut in this example.

You might consider this as you consider the tooth load and stress to the band when you are considering long band life... Now back to our subject.

#3. Hardness of the Lumber - the hardness of the lumber definitely effects tooth load and stress on the band body including the gullet stretch. The hardness of the knots also affects the tooth load. This is something that cannot be controlled. It does however need to be a part of the thought process when considering tooth load. Always consider the hardness of the knots as compared to the soft part of the lumber. In some cases the knots are 10 times harder than the soft portion of the tree. This causes us to saw at a pace that will saw through the knots with proper tooth loads and stress.

What does Horsepower have to do with tooth load?

Horsepower has plenty to do with tooth load. Let us consider most mills, whether sawmills or resaw, having an independent feed motor that is not connected to the power source that drives the bandsaw. While sawing with low hp, if the saw blade hits a hard knot the tooth load increases immediately and the saw under low hp starts to slow down. At the same time the feed motor has no way of knowing that the band has dropped in speed and gained a greater tooth load in two ways: The first is in the harder bite of the knot and the second is with the slowing of the bandsaw which increases the amount of bite per tooth of the harder wood. Because the lower hp cannot hold up to the increase of tooth load the band stress will cause the band to cut badly.

“What if we use higher hp even to the point that it appears that we are over-powering the saw blade?” What this does is very good: First it eliminates the #2 reaction described above in that it allows the band to continue at a constant speed that maintains a constant tooth bite insuring that the band does not take on additional stress due to increased tooth bite size in an area that it would be preferred to decrease the tooth bite. Higher horse power will also allow for the bandsaw to be turned faster, therefore allowing us to put more teeth through the cut per second allowing us to keep the tooth load low while sawing at faster feed speeds.

A word of caution, when using faster band speeds with the higher hp! - When spinning the band faster the band wheels must be accurate. This means they must be perfectly round holding a very tight tolerance. I prefer less than .010” tolerance. Balance is very important also. If the band wheels are out of round they will cause the bandsaw to flutter. If you look eye level from the back side of the band, the band will appear to be thicker than it actually is. This flutter will cause the band to break prematurely. At Cook’s Saw we grind the wheel to a perfect roundness to insure that they are perfectly round. (Idle & Drive side band wheels are available on pages 28-29).

So how does a sharpener improve cutting performance?

As I have explained the need for keen sharpness, you should understand that sharpness is something that can be controlled. We have some customers using our sharpeners who like to sharpen new bands before they use them. They know that the band will perform better and give a longer life span if they tune it before using on their mill. A new band, straight out of the box, would be rated around a 7 in ability on a scale from 0-10 with 10 being the best and 0 too dull to use. The only band that I can rate a 10 out of the box is a Cook’s Super Sharp™.

A sawyer can fine tune the new band by checking the set and setting if necessary. Then lightly sharpen the face of the tooth and maybe very lightly on the top. The band will then be rated at 10 and able to perform at peak cutting rates. Again, if you are currently using Super Sharp’s there’s no need to sharpen them out of the box.

What are band blade companies doing when they sharpen a new bandsaw anyway?

Let’s consider what we find on a new band. The new bands are milled on production machines that make the face 90 degrees square with the body and the top 90 degrees flat on top. Then the band is set. If the factory has good setting machines and tooling, the face will turn sharply and the top will lean over, of course not square anymore and the face will have more negative effect than the top. The face will have a 12 degree negative face angle, which makes the tooth a scraper rather than a cutter as it is introduced to the wood to cut.

By lightly sharpening the face, the angle is restored to 90 degrees square and has about a 20 to 30 percent better cutting angle for the tooth to do its job and you can hear the difference when it hits the wood. In some cases where the sawyer is sawing very hard wood it is a necessity to sharpen before using the new bands and then sharpening often as they dull to get accurate cuts.

The Truth About Sharpening Equipment

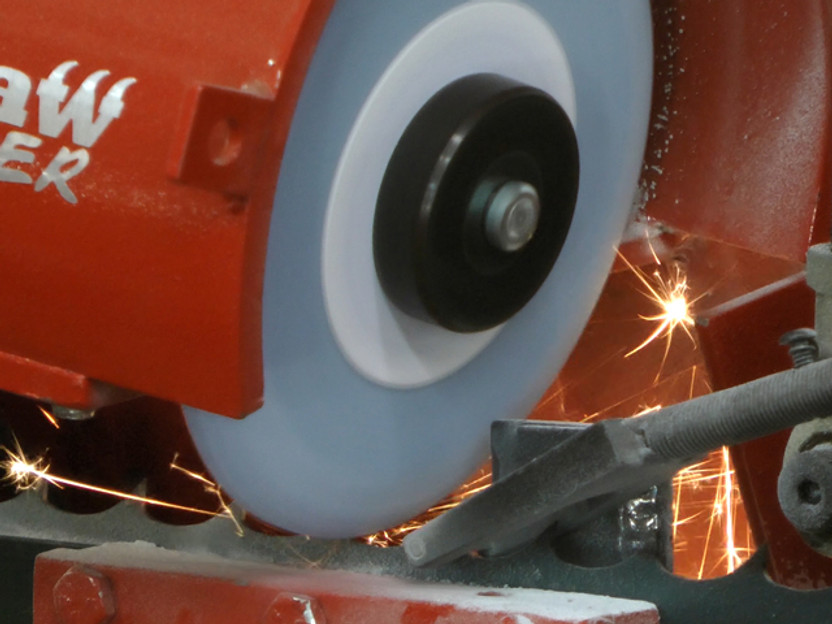

A lightweight sharpener will not hold correct tooth face angles. In this case we are talking about the hook or how far the tooth leans toward the intended line of cut. When the grind rock is falling toward the top of the tooth face it starts to grind the face and it is absolutely necessary for the grind rock to remain steady for the purpose of keeping correct angles and giving a very sharp tooth. I have heard many people complain who were sharpening bands and having trouble because of a lightweight sharpener. What was happening as the grind rock started to grind the very tip point was that the rock would grind a few thousanths down the face and then begin to flex and move over causing the tooth on the cutting edge to be rounded instead of very keen and sharp. In some instances the frame flexes and in others the grind rock shaft has end play in which the rock moves over as it touches the tooth. In other cases both flex and shaft movement are present. This will result in a tooth that will not perform like a tooth should. The band actually saws like a dull band just because it is not sharp.

What you’ll find in the Cat Claw frame is that it’s very stout and steady (the Cat Claw weighs 175 lbs.). The grind rock shaft is ridged and locked into the bearings and this gives stability that is necessary for that keen razor edge. One other thing that makes the Cat Claw the best choice is a poly vee belt that is flat and flexible. This belting system is 5 times smoother than v-belts, giving that razor sharp edge that is much needed.

The clamping device is the next consideration:

The clamping device that holds the band steady while it is ground must be steady or the band will move and if the band moves it cannot be sharpened to a razor edge. The Cat Claw clamping device is very stout and spring loaded which allows the band to be indexed and remain in place while being ground.

The next consideration is the cam, which dictates how the grind rock follows the profile of the tooth. The cam must be ridged and the shaft that holds the cam must not flex. If there are irregularities in the cam it will not be good for sharpness. Also the gullet must be ground as smoothly as possible to keep the band from breaking. The Cat Claw has a ridged and stout camshaft and the cams are all steel. The cams are ground to a perfect shape and fitted to each grinder. They allow for superb tooth shape and profile and give a smooth gullet and even flow up the back. The cam allows the rock to fall down the tooth at a slower rate than they grind up the back; this gives the face a razor sharp tooth from the face grinding action. In addition the cam flows smoothly from the tip and transfers into the gullet smoothly and makes the transfer change to rise up the back for a smooth back grind. All combined this gives the absolute best grind that can be achieved in the field.

What are the money savings?

I will answer this in general. There is no definite answer because there are so many applications and types of wood along with different bandmill types. I usually tell people that if they are sawing lumber and their band costs are equivalent to .01 (one cent) per board foot they have done well and their band cost are economically effective.

If a person does not sharpen his own and pays a sharpening service, he will usually pay .015 (one and 1/2 cents) per board foot.

I have a lot of customers who sharpen with the Cat Claw that have their expense down to .005 (1/2 cent) per board foot.

Other Advantages when using sharpening your own bands.

You are in control of your bands and your business. If you choose the best most cost effective blade sharpening equipment, I can assure you that your equipment will pay for itself over and over.

aka... the "Saw Doctor"

Co-Owner CooksSaw.com

Leaders in Bandsaw Technology!