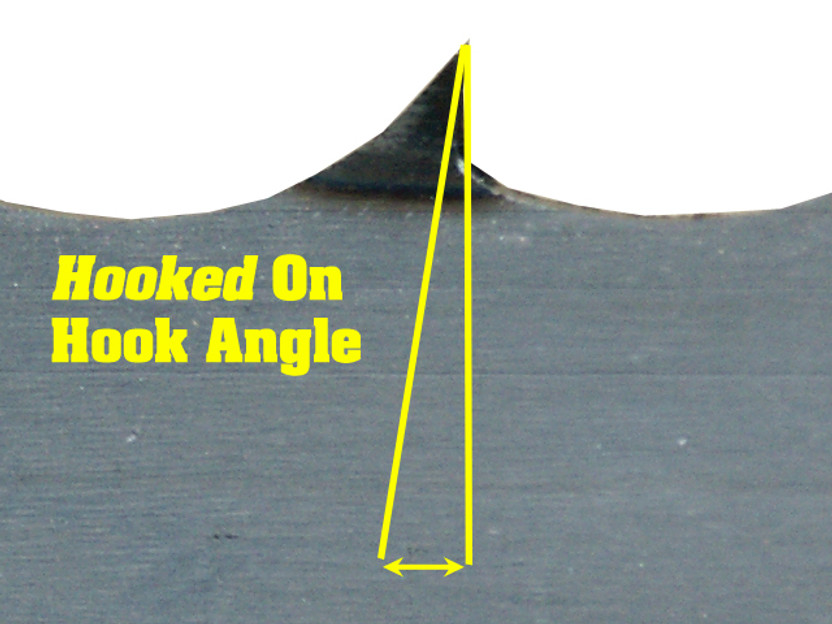

Hooked On Hook Angle

Posted by Tim Cook on Jan 14th 2019

With the increase of bandsaw blade marketing in terms of ‘hook angle’ there is also an increase in questions that arise as to how hook angle actually affects blade performance. So the

question of the day we are hearing right now is “What is hook angle, and which hook angle is best for what I am cutting?”

question of the day we are hearing right now is “What is hook angle, and which hook angle is best for what I am cutting?”

To answer this and other hook angle questions let’s first look at exactly what hook angle is and then we can determine how it affects your blade.

Hook angle is best understood if you think of holding a knife in your hand and shaving a piece of wood. We’ve probably all done this as kids with our first knife; we find a stick and shave it to a fine point because it’s great for jabbing…things. The angle at which we held the knife to shave the stick is (in this case) the hook angle. .

With a knife we can see that leaning the knife into the wood (more hook angle) it will shear the wood away like it should. However if you stand the knife at 0 degrees or straight up, it becomes a scraper and cannot cut the wood fiber but can only scrap the wood. For an easier mental picture I’ll refer to hook angle as ‘shear angle’ because that is what is actually taking place; the tooth of the blade or in this case our knife is angled so it can shear the wood. If fact each tooth of the bandsaw blade functions like a little knife.

Another good example is a road grader: when the angle of the grading blade is increased, we find the dirt that is picked up on the leading point is shifted down toward the trailing edge faster. The more the increase in angle the quicker it moves the dirt. Now consider if the grader moved the blade to angle of 0 degrees. The dirt that is graded would spill right over the top because it cannot be shifted to the side because of the angle of the blade.

The saw blade tooth has the same effect as the road grader. The more hook angle we add, the faster the sawdust is generated and transferred to and past the gullet. As a result the sawdust is no longer contained where we desire it to be. Sawdust that is not removed by the gullet then becomes a catalyst for friction in the cut. This sawdust will heat the blade and will require you to slow down your sawing speed. So we want to find a hook angle that does not send the sawdust toward the gullet with such great force and speed so as to force the sawdust by the gullet.

Keep in mind a cool blade is a stronger blade, and a stronger blade will saw faster. The faster we saw, the larger the dust particle will be and as a result, will remain in the gullet to be carried out of the cut, thus increasing production. On the contrary, the more the sawdust packs by the gullet, the more friction from the dust we get, and the hotter the blade will get, and the hot blade must be slowed down. As a result we are forced to slow down our cut, which creates smaller particles, and the smaller particles are what pack outside of the gullet causing a loss of production. So generally less hook angle will carry out the sawdust better.

There is a lot of confusing information to be found on this subject and it is often the result of a genuine lack of a full understanding of just how many factors determine how a blade will saw. For example: I remember a customer that was sawing pine. I sharpened the blades with 12.5 hook angle. The customer called and said that the blades were grossly mis-set. I went and watched them saw and found that the blades were gouging the log and the lumber as if they were set bad. The gouges were .020 deep. I checked the set and they were set within .002 which is right on target. So I dropped the hook angle back to 10 degrees and the gouges disappeared. My customer said “You finally got the set right.” I tried but could not convince him that I just changed the hook angle to 2.5 degrees less.

Too much hook will cause scoring of the wood to resemble bad set.

In this case hook angle solved the problem, but hook angle is not always the cause or the cure for probably the most encountered issue in the sawing business; rising or diving blades. Those are blade body flatness issues. To change hook angle is like trying to cure the symptom instead of the real problem. Solve the blade flatness issue and you’ll alleviate a big amount of all your blade issues. Of course if you’re buying your blades from us we can help you solve these problems. If you don’t already buy your blades from us I would encourage you to compare us to anyone selling band blades for the knowledge we provide as well as the quality of the product.

I can confidently tell you that if your blade is rising or diving and you are in the 8 to 10 degree hook angle range, hook is not your problem. Sawmill alignment or other blade issues cause blades to rise or dive.

I’ll leave you with a general guideline for hook angle:

In softer wood where the wood fiber is soft it is conducive to effortless sawing that more hook angle should be used. In the case of softwood the increased hook angle helps to cut the fiber with less force. In contrast, hardwoods such as red oak and hickory do not require as much hook angle simply because the fiber is stiff and by design it shears better with less hook angle.

Conclusion: less hook angle takes dust out better. More hook angle shears fiber better but packs sawdust more. I believe the balance is 8 degrees in hardwood and winter sawing and 10 degrees in softer wood and summer sawing. Each person will find what fits best using these guidelines.

Tim Cook